Mobile Physical Inventory streamlines and improves the physical inventory process with real time scanning of inventory counts controlled by tags, along with count audit and approval functions. In addition, the cycle count process is improved with automatic update of count dates.

Physical Inventory users have realized significant benefits with their first cycle count using this solution:

• Streamlined physical inventory count processes reduces

labor/overtime costs.

• Reduced production downtime needed for count/reconciliation.

• Improved inventory accuracy.

• Integrates cycle count and physical inventory date management.

‘Tag’ labels control the physical counts. Each Tag includes a unique bar code. The counter is not required to write any information; they scan the tag, item, location, batch/lot (if applicable) and enter the quantity. They leave the tag on the item/location to show that it has been counted. Tags can also be flagged as either ‘void’ (with a user defined reason code) or ‘unused’.

After counting, the audit function provides review of the count, which can be accepted or rejected. If rejected, the auditor enters a user defined reason code and an optional comment, explaining the reason for the rejection.

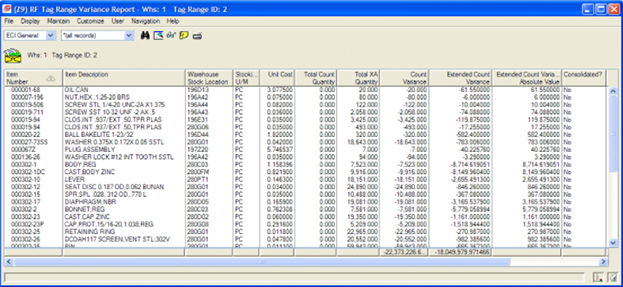

Tag information is presented in a PowerLink view and shows count/counter, audit/auditor and variance information.

When all tags have been counted and audited they uploaded to XA through a Count Group or Physical Inventory Batch.

The solution also improves the cycle counting process by automatically updating the Cycle Count Code, which is used by XA to recommend a cycle count. It also eliminates the problem when ‘last count date’ is reset for all items at the time of Physical Inventory update. After physical inventory, ‘last count date’ field is updated with prior dates calculated using the Cycle Count Code and XA Calendar file.